Home

It is stated that barley used in beer production contains approximately 60-65% starch, almost all of this starch is fermented into alcohol and carbon dioxide during beer production, and other nutrients and minerals remain in the pulp, condensing three times more.

Allen and Stewenson report that since almost all of the soluble or fermentable carbohydrates are removed during beer production, most of the remaining carbohydrates consist of raw cellulose, 25% of the raw cellulose in barley pulp is converted into simple sugars, and the water-soluble carbohydrate content remains around 6.92% - 8.95% in dry matter. Smith states that this amount of soluble carbohydrate is sufficient to obtain good, high-quality silage.

It is stated that barley pulp contains around 28% crude protein and 23% digestible protein in its dry matter, and this amount is equal to much more corn gluten than wheat bran. It is stated that barley pulp is a source of selenium. It is reported that the calcium and phosphorus content of barley pulp is three times that of the barley used in beer production.

The nutrients and energy content of fresh barley pulp are shown in Table 1.

H. PROTEIN (%).................................................: 27.84

H. FAT (%)............................................................: 9.92

STARCH (%)........................................................: 6.96

M. ENERGY (Kcal/kg).......................................: 2310.54

CELLULOSE (%).................................................: 30.21

ASH (%)...............................................................: 4.27

MOISTURE (%)...................................................: 74.45

NITROGEN-FREE EXTRACT MATTER (%).: 6.21

NOTE: M. ENERGY IS CALCULATED ON DRY MATTER.

If the process of reducing the water content of barley pulp is done by heating, the digestibility of proteins and carbohydrates is negatively affected. Removing water from the pulp by mechanical processes causes the loss of water-soluble nutrients.

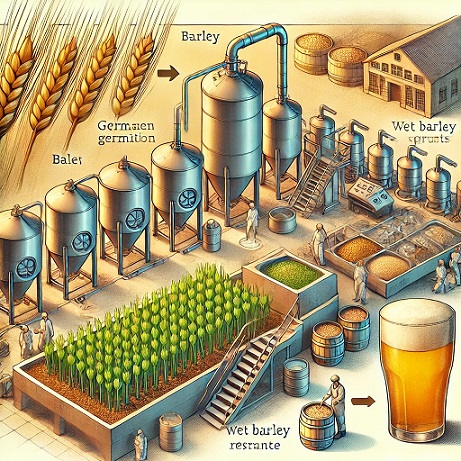

In beer making, barley and in addition to this, rice or corn are used as a secondary grain that supports fermentation.

As the first step in beer making, barley is soaked and left to germinate for 2-3 days. During germination, which is carried out in a funnel-shaped tank, water is filled to completely cover the barley for 2-3 hours and during this period, air is given into the water in order not to stop the activity of aerobic enzymes. The water is then drained and the barley pulp is kept wet for another 2-3 hours. This process is repeated until the end of the germination period.

During germination, enzymes that convert starch into dextrin and maltose are released. After germination, the barley is dried and the grass called malt sprouts are separated. The remaining part is malt, which is crushed and diluted, and to support fermentation, an auxiliary grain consisting of rice or corn is added and gradually heated to 75 °C to provide the activity of various enzymes. The main enzyme activity occurs in this stage called "mashing" and almost all of the starch in the grains is converted into maltose and other sugars. After the "mashing" process, wet barley pulp remains. Hops are added to give the beer its typical smell and taste.